20 Jul, 2023

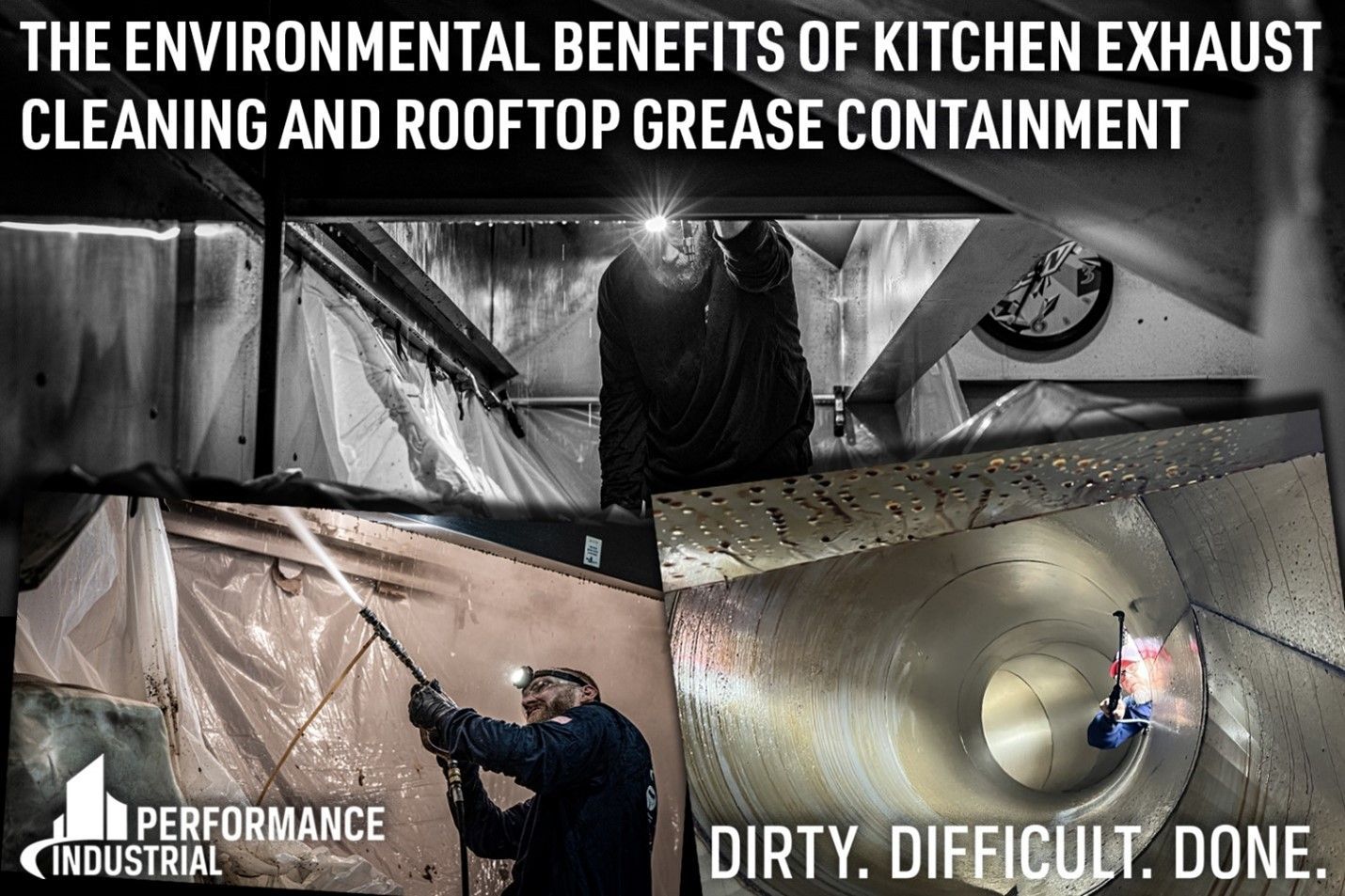

Performance Industrial frequently completes jobs that are just a little different from what you would normally see. You will find our team tackling some dirty jobs in some of the most hidden, out of sight areas. This may cause some to wonder what it is we do exactly. To put it simply, we believe in using the power of industrial cleaning to help our clients maintain brighter, cleaner, safer, and more professional workspaces. We understand that each project impacts the world in a different way and our goal is to help make the world better with project completion. Through our professional industrial services, we can make a world of difference in a facility’s quality, safety, and energy performance. Performance Industrial’s drive for excellence began with its original brand Americlean, when it was founded in 1986 by Mark Miller, who sought to fill the need for professional, industrial cleaning in his own community. As the business grew, he sought out training and certifications for his team to provide the highest level of services to his clients. Through his mission, the business was fully established offering an array of industrial services from sandblasting and flooring systems to kitchen exhaust cleaning. In 2014, the Americlean team came together to assess their specialties and future goals. Through the many years of serving their clients, they found that their seamless, professional performance was what their clients valued most in their industrial cleaning services. Taking this to heart, they decided to rebrand and became Performance Industrial . Mark brought his hardworking son Bill, and daughter-in-law Karen, into the fold and they purchased the business on December 31st, 2019. Through their leadership, they understand that each project impacts the world in a different way, and they continue to help make the world better with each one. Performance Industrial continues to evolve and expand their services to make a difference in a facility’s quality, safety, and energy performance. But, what types of services do we offer exactly? Performance Industrial is your one-stop shop for commercial and industrial cleaning and coating needs. Since 1986, Performance Industrial has over three decades worth of experience in industrial cleaning and coating applications. Our commitment to superior safety standards , exceptional customer service, and emergency services makes us the number one choice in New York, New Jersey, New Hampshire, Vermont, and Massachusetts. Performance Industrial specializes in the following industrial services: 1. Painting & Epoxy Floors We specialize in commercial painting, industrial coating, marine coating, industrial applications, waterproofing membranes, and epoxy flooring. In addition to painting your facility, coating or sealing your floors is one of the best ways to improve the overall appearance of your facility. 2. Sandblasting & Pressure Washing Skilled and knowledgeable in removing defects from surfaces such as paint, rust, grease, mold, or simply built-up dust. Our team members are qualified in media blasting, power washing, painting, and stripping, with hands-on experience that allows them to adjust according to the needs of each project. 3. Industrial Cleaning The complexity and depth of our industrial cleaning is truly what sets us apart from the competition when it comes to industrial facilities, power plants, smokestacks, food processing facilities, manufacturing facilities, warehouses, and pharmaceutical facilities. Dirt, oil, dust, you name it, all accumulate in these environments. We specialize in performing a thorough cleaning with various tools and techniques depending on our client’s needs. 4. Kitchen Exhaust Systems Cleaning of kitchen exhaust systems, industrial chimneys, and HVAC duct work requires a professional and efficient cleaning team. Performance Industrial’s crew leaves no duct or surface untouched for a complete down to the metal clean. We meet and exceed the NFPA-96 standards and hold certifications from: International Kitchen Exhaust Cleaning Association (IKECA) The State of Massachusetts Do you need a long-term solution for all your industrial cleaning needs? Let Performance Industrial make a difference in your facility’s quality, safety, and energy performance! With one call, your facility will be brighter, cleaner, safer, and more professional. No matter how grimy the job is, we show up on time and in uniform to make it happen. When you need a single source and expert execution, you can’t afford not to hire us .